Inventory Control

What is Inventory Control?

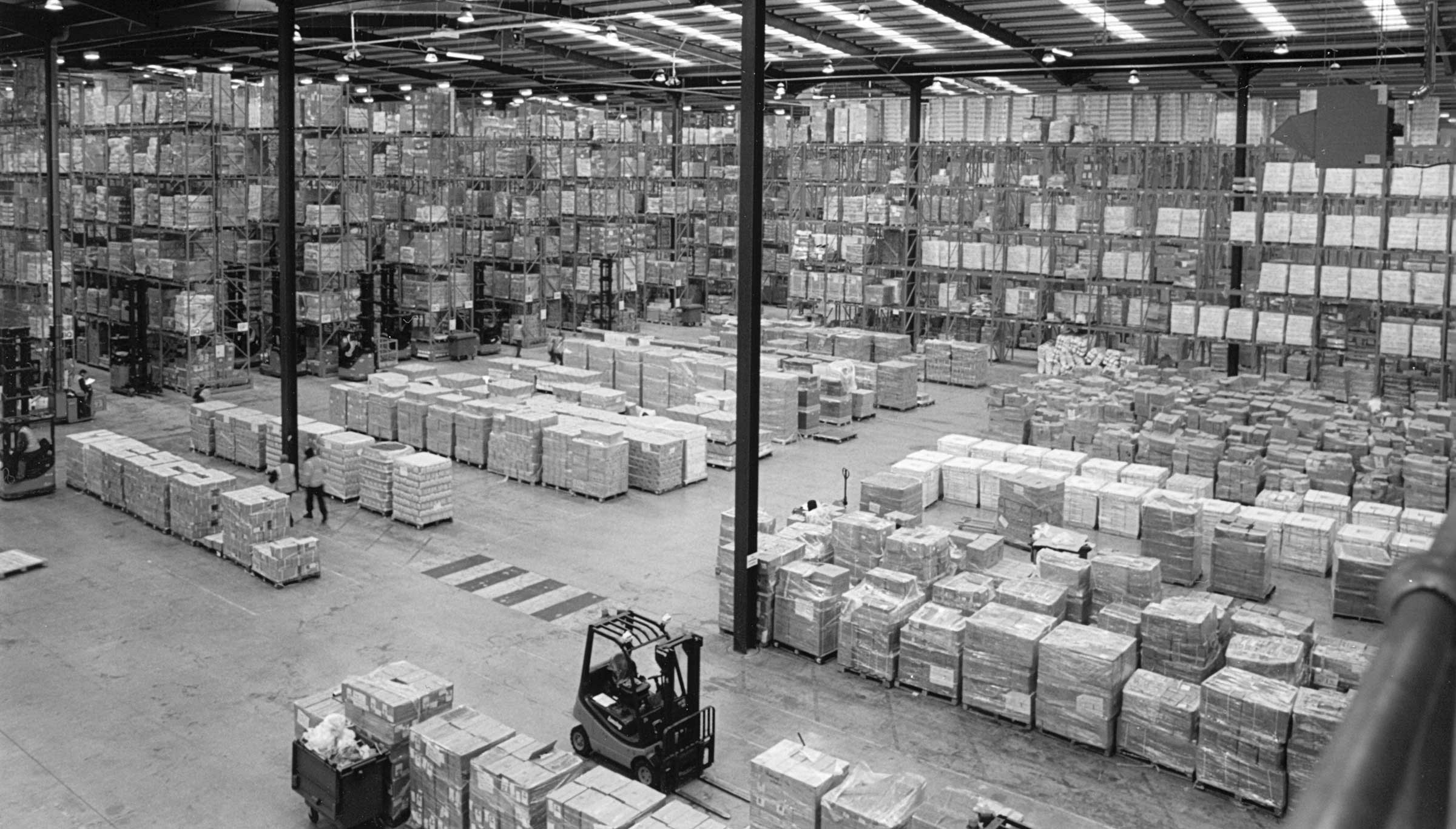

Inventory control is the delicate balance of the costs versus profits associated with having stock on hand.Inventory control means keeping the overall costs associated with having inventory as low as possible without creating problems. It is an important part of any business that must have a stock of products or items on hand. Correctly managing inventory is a delicate balance at all times between having too much and too little in order to maximize profits. The costs associated with holding stock, running out of stock, and placing orders must all be looked at and compared in order to find the right formula for a particular business.

It is impossible to have an unlimited supply on hand, for a number of different reasons. Many businesses simply don’t have enough money to keep excessively large inventories. There are costs associated with purchasing the items as well as storing them, and having too many products leads to further losses when they don’t move off of the shelves.

At the same time, there are issues with inventory control when there isn’t enough stock on hand. One common problem is running out of inventory, which is caused by trying to reduce inventory costs too much. This is something that no business wants to have happen, but it happens to virtually all of them at some point. Even the largest stores run out of certain products from time to time when they sell or use more than they expected. This can cause financial losses when inventory is not available for customers to purchase. Part of inventory control is trying to minimize shortages so these are rare occurrences. Most businesses expect they will have shortages on occasion and they have calculated that the small loss is worth the money saved by not having an overstock.

Another important element of inventory control is the reorder point. Businesses need to think ahead and calculate the best time for reordering products. Doing so too soon may cause financial difficulties or running out of space. On the other hand, waiting to long to reorder will result in a shortage and running out of inventory before the next shipment arrives. When figuring out a reorder point, it’s necessary to calculate how long it will take the shipment to arrive and the amount of demand for a particular item. The overhead costs, fees, and shipping expenses of ordering large versus small quantities should also be looked at.

Inventory control is an ongoing process that is rarely, if ever, executed perfectly. Sonical Logistics’s Experience, expertise, and practice help you to make the best decisions regarding stock, but there are always unknown circumstances and variables. Stores can make good estimates about how many of a specific product they will sell, but they get things wrong from time to time. This is unavoidable. Inventory control can break a business if it is executed poorly, because either expenses will be too high or customers will get tired of dealing with shortages and find another place to spend their money.